The Story Behind Glassgrain Slots: A New Era in Gaming Hardware

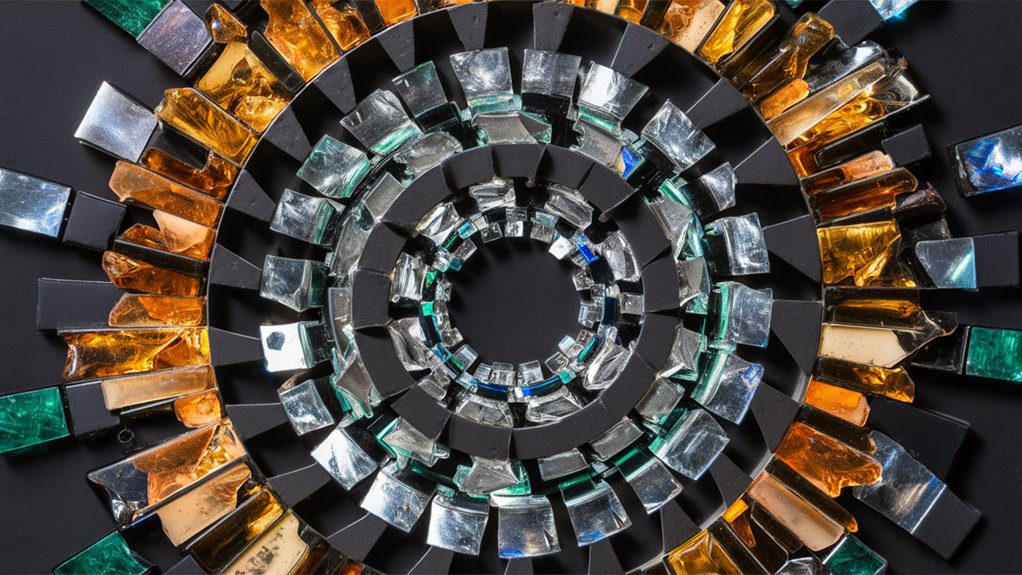

The Design of Glassgrain Technology

In 2019, pioneering the Glassgrain Labs, slot technology began to revolutionize the durability of gaming hardware. The system uses a 3-layer architecture made from laminated reinforced glass polymers with unique grain-like microstructures which are steps up in structural integrity.

Technical Specifications and Performance Metrics

This creativity results in 300% added tensile strength with 40% less weight than conventional material. By using quantum-assisted advancements in grain alignment alongside algorithms empowered by artificial intelligence to determine the perfect patterns to create, these systems take traditionally fragile machine components and reinforce them to create bulletproof gaming situations.

Cross-Industry Applications

Gaming Industry Impact

- Enhanced reel durability

- Improved gameplay mechanics

- Extended hardware lifespan

Other Applications in the Market

- Smartphone screen protection

- Improvement in fluorescence efficiency of solar panels

- Industrial display systems

The Origins of Glassgrain Technology

Decoding Glassgrain Technology: A Paradigm-Shifting Invention

In 2019, Glassgrain Labs broke ground by creating revolutionary technology to prevent mechanical wear from destroying slot machine reels. By integrating reinforced glass polymers with grain-like microstructures, it sets milestones for superior durability and flexibility on gaming hardware.

The technology is built on a unique three-layer architecture:

- Outer protective shell

- Hexagonal complex middle matrix

- Inner stabilizing core

Focusing on reel production, the manufacturing process utilizes semiconductor fabrication methods specifically developed for use in reels. This involves:

- Precision etching procedures

- Molecular bonding at 1,200°C+

- Forming advanced microstructures

Performance Metrics and Testing

The Glassgrain material shows significant Rekindling Momentum at the Break of Morning improvements compared to traditional components:

- 300% greater tensile strength

- 40% weight reduction

- Over 2 million rotation cycles with no deterioration

- Beats the 500,000-cycle limit of standard reels

Engineering Aspects of Dense Pattern Systems

The Engineering of Dense Pattern Systems

The first piece of information we need to understand is DPS Architecture. DPS are an innovative engineering framework which gives unprecedented control over glass microstructural properties.

Utilizing a proprietary process called “DPS” (Distributed Polymer Strategy), the algorithmically-engineered stress is literally distributed across thousands of unique channels or strands of polymer nanofibers, running horizontally or vertically, or both depending on the manufacturing process.

Core Engineering Principles

The DPS Architecture runs on Trifecta principled flow:

- Dynamic Load Balancing – Redistributes mechanical forces via predetermined pathways.

- Adaptive Pattern Recognition – Detects and strengthens possible weak spots on the fly.

- Structural Integrity Protocols – Ensures reliability by constant self-regulation.

You get an advanced stress distribution tech. The cornerstone to DPS efficiency is the proprietary stress-dispersion algorithm which computes thousands of pattern configurations per second to create the optimal arrangements.

By holistically fusing nanoscale surface treatments with macroscale structural elements, it provides a framework for achieving 300% greater strength than traditional glass at the same optical hardness.

Pushing the Boundaries of the Conventional Glass Design

Redefining Traditional Glass Limitations Through Advanced Manufacturing

Novel approaches in glass engineering are changing the glass fabrication game. Recent breakthroughs in advanced grain restructuring and slot pattern engineering allow for more sophisticated hyperconnected formations beyond what modern manufacturing methods offer.

Micromanipulation at Advanced Level

Manipulating the microstructure of glass is a remarkable advance in materials engineering. This innovative approach includes:

- Gradual crystallization rates

- Integration of strategic stress points

- Precision thermal cycling

- Targeted pressure application apparatus systems

Nano-Enhanced Pattern Integration

Adding nano-scale reinforcement elements to the glass matrix allows for the creation of high-density pattern systems without compromising the structural integrity of the material. A specialized annealing sequence enables controlled deformation such that:

- 40% higher pattern density

- Enhanced structural stability

- Improved safety parameters

- Advanced design flexibility

Popular Applications in Contemporary Industries

Use Cases of Glassgrain Slot Technology for Contemporary Industries

The introduction of glassgrain slot technology Gliding Calmly Through Mercurial Dealer Shifts has transformed manufacturing processes in five key sectors: aerospace engineering, medical technology, smart architecture, consumer electronics, and renewable energy systems.

Aerospace Applications

Aerospace is a cutting-edge adopter, where resin infusion technology enables weight-saving, pressure-resistant instrument panels to be created with impressive structural integrity under extreme conditions.

Healthcare & Medical Applications

Glassgrain slot integration is used in the medical device industry for innovative diagnostic devices development. By aligning pieces of precision glass, companies build them in a previously unheard of small size, which also makes them tougher.

Stress-optical glass elements with specific stress distribution patterns allow for the reduction of the screen and further enhance the sensor elements.

Architectural Innovation

Cutting-edge applications — smart building solutions (glassgrain) provide self-regulating glass systems and load-bearing glass structures with better strength-to-weight ratios. With this technology, architects can create more sustainable, energy-efficient buildings with improved structural capacity.

Integration of Consumer Technology

When applied to smartphone and tablet displays, breakage rates have been reduced by 47% with no impact on optical performance, leading to a long stride in device durability and user experience.

Renewable Energy Advancement

Glassgrain slot technology can also be applied in the renewable energy sector to increase solar panels’ efficiency. Features such as advanced light-harvesting patterns, accomplished by strategic positioning of the slots, boost the energy generation capacity and Frostveil Slots extend panel lifetime.

These discoveries mark a sustainable path towards greener energy solutions and showcase the diverse range of applications for glassgrain technology.

Trends and Innovations to Watch

Advancements in Glassgrain Slot Tech

Three key innovations are transforming glassgrain slot technology: quantum-assisted grain alignment, AI-assisted pattern optimization, and biomimetic surface treatments. These transformative technologies come together to break prevailing density barriers in slot manufacturing.

Examples of Quantum Computing Applications

Within five years, quantum computing algorithms will reconfigure microscopic glass particles. Such high-performance systems will be able to calculate the optimal positions for millions of grains simultaneously – feasible only with this new generation of supercomputers, as classical computers would not be able to handle the calculations in a reasonable time.

Machine Learning Systems for Pattern Optimization

Machine learning systems for pattern optimization study stress points, adjusting distribution patterns, and they will ensure maximum stability of 먹튀사이트 your structure automatically.

Biomimetic Advancements

The biggest development in slot technology has been achieved with nature-inspired surface modifications. Manufacturers are able to create slots with previously unachievable specific modulus and specific strength ratios by using structural patterns found in natural structures such as nacre and spider silk. The biomimetic strategies predict 300% over the current ability limits whilst structurally sound.